Vegetable / Fruits Dehydration Plant

Vegetable / Fruits Dehydration Plant

In International Market it is surprising but true that the agriculture products are not processed and gets wasted due to lack of cold storage. Vegetable/fruits can be stored for quite long time periods providing the fruits/vegetable are dehydrated to reduce water content. This way we can store them and even export lot many fruits and vegetables like ginger, garlic, onion, chilly, etc.

In International Market it is surprising but true that the agriculture products are not processed and gets wasted due to lack of cold storage. Vegetable/fruits can be stored for quite long time periods providing the fruits/vegetable are dehydrated to reduce water content. This way we can store them and even export lot many fruits and vegetables like ginger, garlic, onion, chilly, etc.

PROCESS DESCRIPTION

A unit has been made to dehydrate vegetables/fruits at low temperature with air re-circulation arrangement. Batch size is approximately 100 kgs. And drying time is about 2-6 hours depending upon types of vegetables.

| Batch Size | : | 40-100 Kgs. |

| M.O.C. | : | All product contact parts SS-304 |

| Batch Time | : | 3-6 hours depending upon moisture to be removed |

SPECIFICATIONS

<| Description | Quantity (Kgs) | Time (Hours) |

| Cauliflower | 100 | 8 |

| Spinach | 40 | 6 |

| Chilli Coriander | 40 | 4-5 |

| Fenugreek Leaves | 40 | 3 |

| Cabbage | 40 | 6 |

| Green Mango | 50 | 6-8 |

PLANT AND MACHINERY

| 1. | Electric Heater | : | 1 Set (12 KW) |

| 2. | No. of Blowers (0.5 KW) | : | 2 Nos |

| 3. | No. of Trays | : | 12 trays (600 x 800 mm) (2 columns, 6 trays in each column) |

INFRASTRUCTURE & FACILITIES

| Space | : | 1.8 x 1.2. x 1.2.m |

| Manpower | : | 2 |

| Electric Load | : | 13 KW |

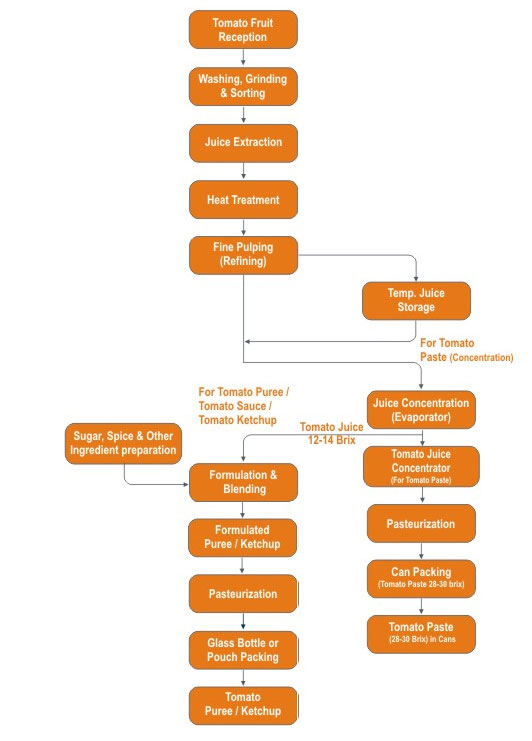

SSP offers complete process line on turnkey basis to produce the following end products from tomatoes. Tomato processing plant gives variety of tomato based dishes which you can enjoy any time.

SSP offers complete process line on turnkey basis to produce the following end products from tomatoes. Tomato processing plant gives variety of tomato based dishes which you can enjoy any time. Packing lines can be offered depending upon the requirement like Product in glass bottles, Cans, Drums, etc. Manufacturing process involves most modern technology of vacuum evaporation using forced circulation evaporators/scrapped surface evaporators. Evaporation plants are versatile in nature and can concentrate other juices also.

Packing lines can be offered depending upon the requirement like Product in glass bottles, Cans, Drums, etc. Manufacturing process involves most modern technology of vacuum evaporation using forced circulation evaporators/scrapped surface evaporators. Evaporation plants are versatile in nature and can concentrate other juices also.